![]() First hardware for HL-LHC interaction region magnets

First hardware for HL-LHC interaction region magnets

by Ezio Todesco (CERN)

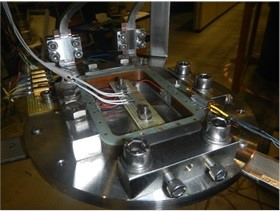

The coil of the sextupole corrector Courtesy of G. Volpini and LASA laboratories |

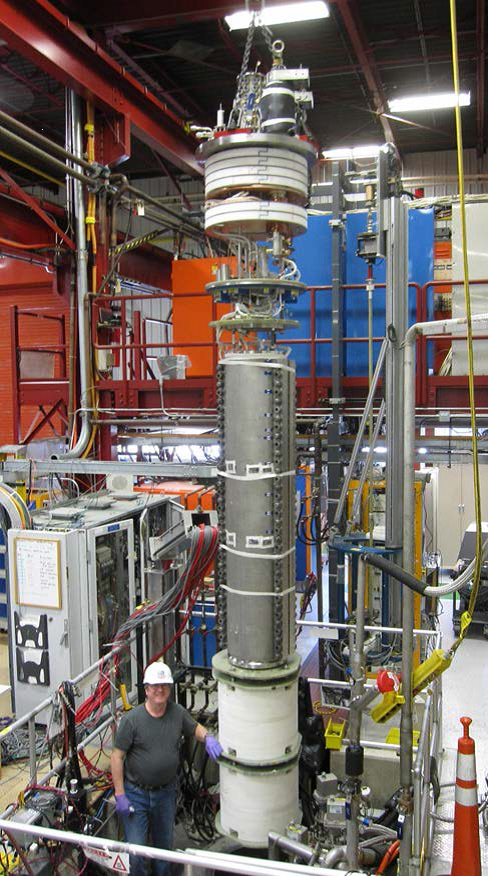

The mirror QXF entering the FNAL test station Courtesy of G. Chlachidze and US-LARP |

The Interaction Region (IR) of the HL-LHC project will be made of nine different types of new magnet, relying on three different technologies (Nb3Sn and Nb-Ti with Rutherford cable, and superferric magnets with Nb-Ti coils).

These magnets are in the design and prototype phase, developed by five international collaborations: US-LARP, CIEMAT (Spain), CEA Saclay (France), INFN-Milano LASA laboratories and INFN-Genova (Italy), and KEK (Japan). The HL-LHC design study is now approaching completion: the conceptual design is nearly finished, engineering is in progress and the first hardware that will be used in the prototypes is being manufactured and tested. This is a very exciting phase as the project shifts from paper to hardware.

In April 2015, the winding and impregnation of the first coil of the superferric sextupole corrector (see image above-left) was completed. As a stand-alone coil it was successfully tested in INFN-LASA laboratories. This collaboration has won the race towards the first test of a component of the HL-LHC interaction region magnets. The coil had a first quench at 80% of short sample limit, and reached 91% after 3 quenches, at 2.5 K. In these correctors, the operational current is set at 60% of short sample limit.

In May 2015, the first short coil of the Nb3Sn quadrupoles, manufactured by the LARP collaboration, was tested in a mirror configuration at FNAL, US. The coil had a first quench at 70% of short sample limit, a second one at 76%, and reached 90% after 20 quenches. The triplet will operate at 75% - this value has been recently reduced from the original 80% value to add some margin, following the advice of the review committee held in December 2014 and chaired by Dr. A. Yamamoto (KEK).

Since the beginning of the year, coil winding tests are going on both in KEK, for the 5.6 T Nb-Ti separation dipole (D1), and in Saclay, for the 115 T/m gradient Nb-Ti quadrupole. In KEK, an iteration of the design of the iron yoke has been performed to guarantee a better alignment of the dipole field during assembly. In CEA, first tests have confirmed the correct geometry of the end spacers and of the coil components.

The next step is the test of the Nb3Sn quadrupole short model in autumn 2015, made up of two CERN coils (just shipped to the US) and two LARP coils. At the end of the year a test of the first corrector sextupole is foreseen in LASA, and a test of the first short model of the separation dipole will be carried out in KEK, Japan.