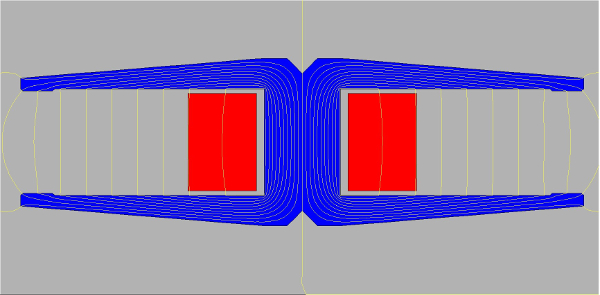

A first concept for the FCC-ee main dipoles, with an X iron yoke (blue) and two aluminium busbars (red). The dimensions are about 40 cm wide per 12 cm high (Image: CERN).

The FCC-ee (Future Circular Collider lepton-lepton scenario) machine requires about 65 km of such magnets, to steer the counter-rotating electron and positron beams, before they collide at the energy of 350 GeV. As the preparation for the upcoming FCC week (11-15th April) is in full swing, researchers from CERN have presented a first concept for the main bending magnets for FCC-ee.

The proposed design for the FCC-ee main bending magnets features a twin aperture geometry, with a common iron yoke and two busbars, operated at room temperature. The dimensions are about 40 cm wide per 12 cm high. The design shows how compact these dipoles could be – at the moment their cross section fits on an A3 sheet. This concept will be further refined, to match the evolving requirements coming from the other FCC-ee work packages, including those on beam dynamics and vacuum.

The idea presented recently is based on a novel layout, where two classical C shapes are arranged back to back to create an unconventional X geometry. The great advantage of the novel design is that the magnetic field in one of the apertures comes at no extra cost, since it is generated by the return conductor of the other aperture. Compared to a system with separate magnets for the two rings, this solution reduces electrical consumption by 50% and of course the number of units to be manufactured, transported, installed and (eventually) removed, for the installation of FCC-hh.

The low fields needed in this case do not require superconducting technology for the magnets, like those used in the LHC and further developed for HL-LHC and FCC-hh (read more).

“The FCC-ee main dipoles require a different type of R&D,” says Attilio Milanese, the CERN engineer who proposed the concept. He explains “at the moment, the focus is to work on the design while optimising the costs and the environmental impact.”

The yoke can be assembled from sheets of electrical steel, of a similar kind used in electric machines like transformers or generators. The excitation current is provided by two busbars in aluminium, which is lighter and cheaper than copper for the same power consumption. Full recycling the raw materials after dismantling the collider is also an option explored, with the team running simulations to understand how these materials will be activated from the high synchrotron radiation emitted by the beams.