![]() A versatile test cryostat for low beta superconducting cavities

A versatile test cryostat for low beta superconducting cavities

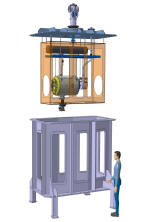

Fig 1: Top-loading of the cryostat with a double spoke cavity. Image credit: TIARA.

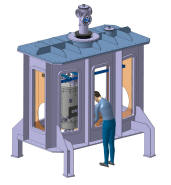

Fig 2: Cryostat integrating a quarter-wave resonator. Image credit: TIARA.

In Work-Package 9 (WP9) of the TIARA-PP project, the IPN Orsay team (CNRS/IN2P3) has raised the challenge of designing a versatile test cryostat capable to host almost all type of fully-equipped superconducting (SC) cavities, including the wide range of low beta structures.

In the process of developing a SC accelerating cavity, the integrated test of the fully dressed cavity (i.e. equipped with its RF power coupler and cold tuning system) in the nominal condition of RF power and temperature is a key step towards the validation of the expected performances of the accelerating structure. To perform this experiment, a specific cryostat is required, adapted to the geometry and configuration of the cavity to be tested.

This type of infrastructure already exists for elliptical-type SC cavities, but not for the low beta structures due to difficulty of integrating the large variety of geometries, configurations and frequencies: quarter-wave or half-wave resonators, spoke or CH-type cavities, single-gap or multi-gap, frequencies ranging from 60 to 700 MHz...

As shown in Fig.1 with a spoke cavity or in Fig. 2 with a quarter-wave resonator, the chosen configuration of the cryostat is a top-loading, where the equipped cavity coming from the assembly in the clean room is suspended to the cryostat top-plate. The various openings located laterally or on the bottom closing plate of the cryostat allow to implement the power coupler and cold tuning system and give access to the cavity for the assembly process and to integrate the instruments. With a length of 2.7 m, a width of 1.5 m and a height of 3.4 m, the cryostat dimension is optimized to minimize the footprint in the test stand but sufficient enough to integrate a string of a SC cavity and a SC solenoid for specific tests.